Company

WE MAKE QUALITY BEFORE EVERYTHING

Our Mission: customer satisfaction

The company’s activities are housed in two neighbouring production units, occupying a roofed surface area of more than 3,500 sq. m.

Thanks to long-standing working relations with other companies, M.C.A, can meet all customer needs.

Continuous innovation

A PROFESSIONAL TEAM AT YOUR PROVISION

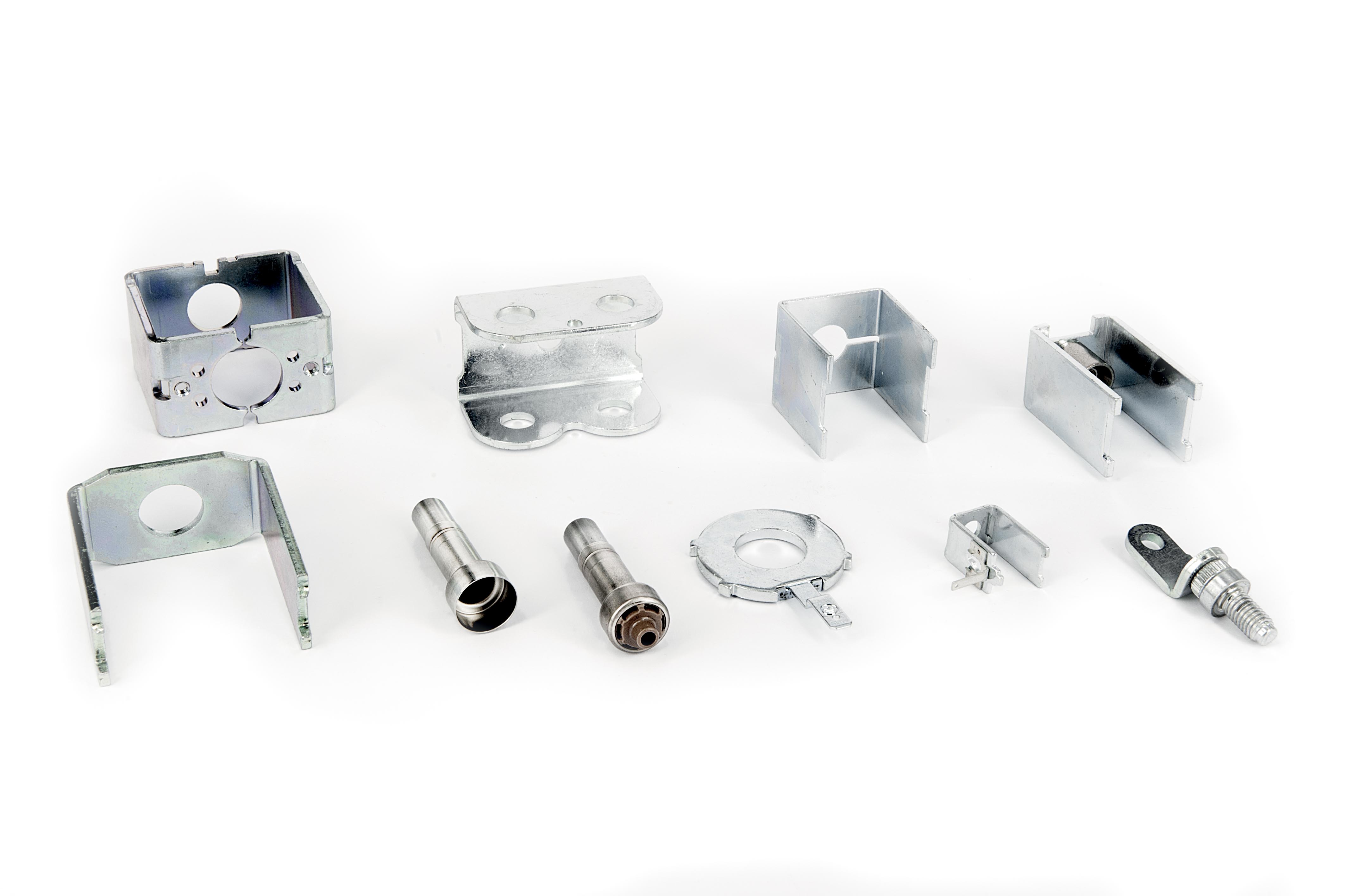

Since 2001, M.C.A. has specialised in nano-valves, micro-valves and small component laser welding. Over the years, M.C.A. has taken over other small companies, has acquired its own equipment and tools, and has developed and increased the capacities of its shearing and assembly departments through considerable investment in high-tech machinery (Bruderer, Balconi and Yamada for its shearing processes; wire-spark erosion, plunge-spark erosion and tooling workstation; automatic machinery for laser welding and assembly).

M.C.A. has always been firmly committed to policies of providing its personnel with ongoing training, while constantly updating its control systems and equipment.